Bronsons’ Services

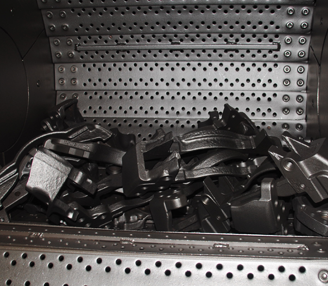

Shot Blasting – Tumble Blasting (peening)

Tumble Blasting is a way of removing surface debris, polishing or strengthening the surface of metal parts. It is used in a multitude of industries which produce metal parts e.g. automotive, off highway, foundry, railway, aerospace and pharmaceutical. The process can be used to remove rust, paint and casting scale prior to the application of any new coatings.

Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metal parts. The process entails impacting a surface with shot at force sufficient to create plastic deformation, it is also used to strengthen and relieve stress in metal parts.

Bronsons’ services include:

• Shot Blast and Shot Peening

• Descaling to remove old coating

• Reduce stress Corrosion and cracking

• Deflashing

• Clean and Polish

Vibro Bowl Finishing – Deburring, Radiusing, Polishing, Cleaning, Drying and Oiling

Vibro bowl machines are used for batch work finishing where parts are required to be deburred, radiused, descaled, burnished, polished, cleaned or have certain protective coatings applied.

Vibro finishing process typically gives parts a smoother surface finish due to the rubbing action of the media against the parts. We use vibro deburring to create a specific radius on pressed parts prior to heat treatment we then use it to polish and clean away any carbon or oil deposits.

After parts have completed their vibro finishing process they are maize dried and packed. Prior to packing we can apply a protective coating.

Bronsons’ services include:

• Deburr

• Radius

• Polish

• Clean

• Remove Carbon and oil

• Dry, Oil and Pack